|

II. Table de carga |

|

Kee Klamp |

Diámetro |

Calibre |

|

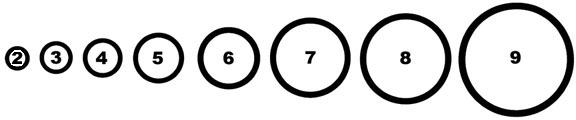

tamaño |

O/D (mm) |

Bore(mm) |

|

2 |

13.5 |

8 |

|

3 |

17.5 |

10 |

|

4 |

21.3 |

15 |

|

5 |

26.9 |

20 |

|

6 |

33.7 |

25 |

|

7 |

42.4 |

32 |

|

8 |

48.3 |

40 |

|

9 |

60.3 |

50 |

|

Specifying

Kee Klamp Fittings |

|

Table de carga de las vigas horizantales For

uneven load distributions or single spans, the required tube size

must be determined by standard bending moment calculations assuming

a Kee Klamp joint to give a simply supported beam. The table shown

below gives an indication only of the safe load uniformly distributed,

in kg, that may be carried per shelf consisting of front and back

tubes when used as continuous beams. Recommended set screw torque:

39 Nm.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Table de carga de las vigas verticales This table gives an indication only of the safe load, in kg., that may be carried between the above restraints by single tubes to BS 1387 (ISO 65) when used as uprights. Loads listed under 'A' columns refer to those loads that are obtainable according to schematic 'A', and loads listed under 'B' columns refer to those loads that are obtainable according to schematic 'B'. Schematic 'B' details a racking system that is mechanically affixed to the surface on which it stands whereas schematic 'A' details a free-standing racking system. Recommended set screw torque: 39 Nm.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||